Welcome to Ruixintai Precise Components Huizhou LTD website!

Polyvinyl alcohol (PVA) was initially employed in Germany and Japan. Later, it was successfully developed and utilized in domains such as the electronics industry, daily cleaning, medical and health care, etc. in China, breaking the long-standing monopoly of electronic-grade products by Japan and achieving self-development and localization.

Our company has consistently maintained the prime condition of production equipment and can readily accept various OEM production requests from customers at any time, supplying the requisite products. We are confident in being capable of manufacturing and providing products that meet customers' customized requirements. For the convenience of customers, we have formulated three major service commitments: product quality, delivery quality, and service quality.

Product quality

Strict management process

1、The superiority&reliability of products

Manufacturing process control

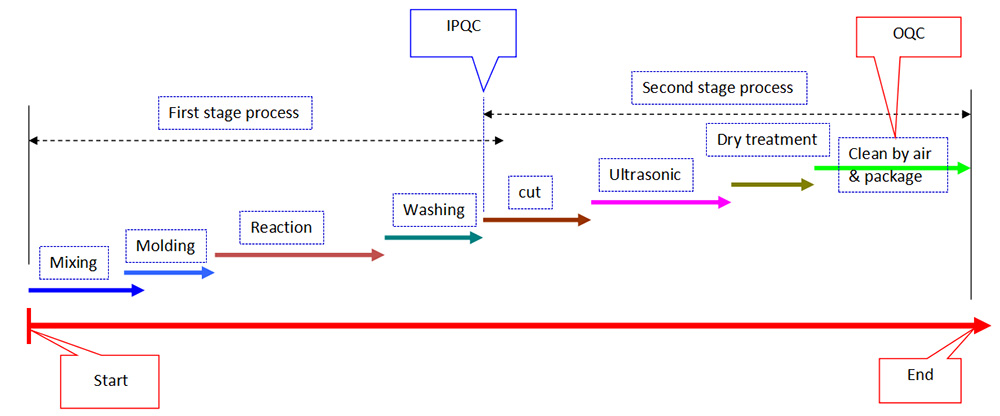

1st period(semi-finished products)

Material-Mixing→Moulding→Reaction→Depanning&infusion→1st products inspection(1st excellent-rate statistics)

2nd period(finished-products)

Cutting→cleansing&dehydration→2nd products inspection(2nd excellent-rate statistics)→dry treatment→clean&pack(3rd excellent-rate statistics)

Finished products quality controlling process

IPQC InPut Process Quality Control→OQC Out-going quality control→SQC Standard Quality Control

IQC→IPQC→FQC→OQC→SQC

2、Quality assurance testing process controling

Appearance-inspection→size-messurement→concentricity test→water-absorption rate test→water-absorbing capacity test.

Strict production process

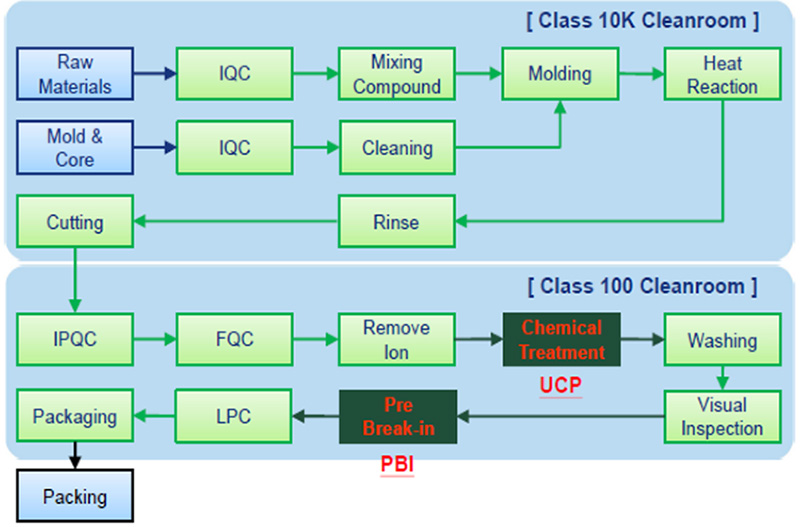

IQC stage (Incoming Quality Check milestone)

Key raw material incoming inspection

. IPQC stage (In process Quality Check milestone)

100% inspection before cutting

. FQC stage (Finally Quality Check milestone)

100% inspection for dimension and appearance after cutting

. OQC stage (Quality check before storing)

100% inspection for products' appearance after packing

Delivery Quality

Stable capacity ensures swift delivery

Service Quality

App support

Process troubleshooting and optimizing、PVA brushes' compatibility with new chemicals、explaining and analyzing performance data、material characterization& failure analyzing

Technical support

Providing free consulting services & technical services

Free samples developing&providing

Analyzing the data of performance&characteristics

Providing authorized third-party test report

PRODUCTS